Making a 450B case from a 7.5x55: A trial run with one case

I thought it would be interesting to try to form a 450B case from a Swiss case. I amputated the neck and shoulder of a 7.5x55 case at the very bottom edge of the shoulder. The length after cut-off was 1.720. I put the case into the Hornady 450B sizer die, with no problems. The shoulder area was less than 450B diameter, so I ran the Hornady expander into the case, producing a notable flare. I trimmed the case to 1.700, and then removed the expansion flare by putting the case into the 450B crimp die and the FL die.

With the case chucked up in my old mini-lathe, I used a file to reduce the rim diameter to 1.473. The rim seemed a little thick, so I removed some metal from the front of the rim. It looked on the exterior like a 450B case. Here's a photo:

.

.

It's evident in the photo that the rim of the formed case is still a little thicker than the 450B case. More lathe work will be needed to remedy that defect.

The inside of the formed case does not resemble a 450B. The case walls are really thick at 0.020, compared with the 450B at about 0.013. The front 0.60 inches of the formed case must be reamed a considerable amount to reduce wall thickness to permit a bullet to be seated properly. It's the same problem that occurs when a 450B case is formed from a 284 case, but the 7.5x55 case has still thicker walls. I don't have a proper reamer for this job, so I stopped working here.

The internal volume of a new 450B Hornady case and the formed case are the same within about 0.05 grains of water. After the formed case is reamed, it will have a bit more volume than the factory 450B case.

My summary thoughts: The conversion can be done, but it's a lot of fiddle-dee-dee work even omitting the inside case reaming. The case will bulge noticeably just above the head when fired.

--Bob

Alternate cases for forming 450 Bushmaster

Moderator: MudBug

Forum rules

Please try and keep it safe!

This information is the responsibility of the community, not the forum. 450bushmaster.net is not responsible if you blow yourselves up.

Please try and keep it safe!

This information is the responsibility of the community, not the forum. 450bushmaster.net is not responsible if you blow yourselves up.

22 posts

• Page 2 of 3 • 1, 2, 3

Re: Alternate cases for forming 450 Bushmaster

Nice job again Bob! Did you measure the diameter of the extraction groove? Given the larger rim, I assumed it would be wider than the stock .284 Win and Hornady cases. If it is, that's a show stopper as well. The first time you try to force it into battery, it will bend or snap the extractor. Sure looks nice and yeah, the web isn't going to fire form, it being solid brass.

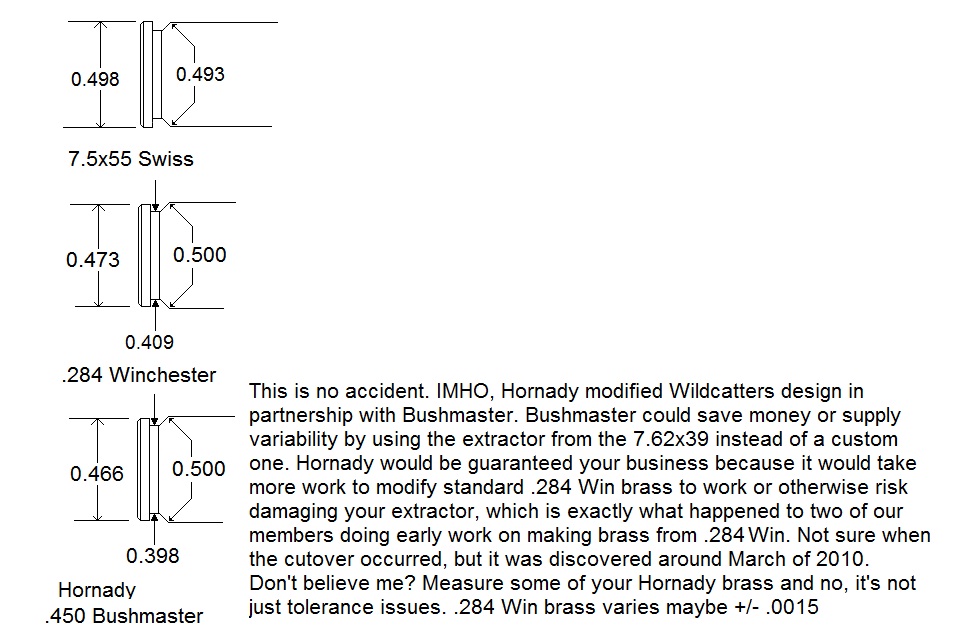

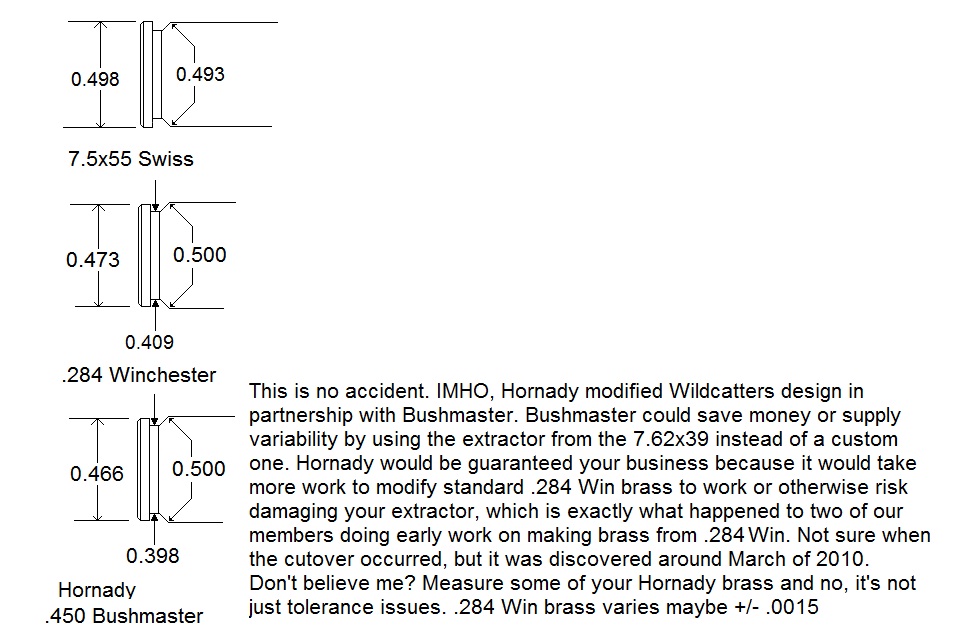

Here's an update to the previous dimensional comparison image:

Hoot

Here's an update to the previous dimensional comparison image:

Hoot

In Theory, there is no difference between theory and practice. In Practice, there is.

-

Hoot - Posts: 5085

- Joined: Tue Feb 09, 2010 9:34 am

- Location: Minnesota

Re: Alternate cases for forming 450 Bushmaster

Thanks for looking into this idea gentlemen. It would appear that it is doable, but not without added expense (could there be a minilathe in my future?). I'm very curious why the 7.5 case would have the same internal volume as the 450, yet clearly has a thicker case wall. Seems counter intuitive. Reaming the case would increase internal volume. I wonder if it would then require another resizing step? Oh well, it was just a thought.

Again thanks for all your work on this pitted bore and Hoot.

Again thanks for all your work on this pitted bore and Hoot.

Iniustus lex est non lex

Melior morior in vestri pes quam ago in vestri genu

Melior morior in vestri pes quam ago in vestri genu

-

boolitschuuter - Posts: 20

- Joined: Mon Dec 17, 2012 9:10 am

- Location: Ste. Gen. Co. MO

Re: Alternate cases for forming 450 Bushmaster

Ok, I get it now and I think Yes, it could be done and boolitschuuter has discovered yet another source of brass for us. It might be a bit of fiddling to get the brass ready for firing, but hey, a source is a source and I don't see anyone beating down doors for for this Swiss brass and I did a cursory check I found the brass everywhere. Even Brownells had it new, for $122.99/100pcs.

The Doc shows the the body size at .493" and the case is going to expand to .501'+, so case life might be short, but 3/4 loadings is good for me and if you keep the pressures down, it might last a long time??

Good Job boolitschuuter and for all of you guys thinking out of the box.

As always, this work is experimental and is out-of-the-accepted-Norm, start low and watch for stress cracks and keep yourself safe, your life may depend on it..

..t

The Doc shows the the body size at .493" and the case is going to expand to .501'+, so case life might be short, but 3/4 loadings is good for me and if you keep the pressures down, it might last a long time??

Good Job boolitschuuter and for all of you guys thinking out of the box.

As always, this work is experimental and is out-of-the-accepted-Norm, start low and watch for stress cracks and keep yourself safe, your life may depend on it..

..t

Safety First..t

-

wildcatter - Posts: 2914

- Joined: Sat Jun 06, 2009 8:30 pm

- Location: In the Middle of Deer Central Station or better known as, in the Thumb of Beautiful Michigan

Re: Alternate cases for forming 450 Bushmaster

Hey Hoot, as you are all laid up and might be feeling a little better, I hope, can you check a couple of measurements for me. What is the body taper angle of the Swiss compared to the 450? and what is the outside case dia at either the bottom of the swiss shoulder or at the 1.700" mark from the base??

..t

..t

Safety First..t

-

wildcatter - Posts: 2914

- Joined: Sat Jun 06, 2009 8:30 pm

- Location: In the Middle of Deer Central Station or better known as, in the Thumb of Beautiful Michigan

Re: Alternate cases for forming 450 Bushmaster

Hi guys, I load for 7.5 Swiss using .284 Win. brass and it works well so I don't see where 7.5 brass would not work.

- lungingturtle2

- Posts: 97

- Joined: Fri Jun 03, 2011 7:11 am

- Location: Manteno, Il.

Re: Alternate cases for forming 450 Bushmaster

wildcatter wrote:Hey Hoot, as you are all laid up and might be feeling a little better, I hope, can you check a couple of measurements for me. What is the body taper angle of the Swiss compared to the 450? and what is the outside case dia at either the bottom of the swiss shoulder or at the 1.700" mark from the base??

T-

This is a first attempt to answer your questions, and I hope Hoot checks the numbers I found. Here's a sketch of the 7.5 Swiss ctg dimensions needed to answer your questions. The values are from the CIP drawing for the cartridge, converted from millimeters to inches. The drawing on the CIP site is here: CIP drawing for 7.5x55 Swiss ctg. As far as I can determine, and it's no big surprise, there is no set of SAAMI specifications for the 7.5 Swiss ctg.

.

.

For the 7.5x55 Swiss, the body taper angle is 0.704°from the cartridge axis, or 1.408° included angle.

For the 450B, the body taper angle is 0.3820° from the cartridge axis, or 1.7639° included.

The shoulder of the 7.5 Swiss is 1.7512" from the head of the case; at that point, the outside diameter of the case is 0.4579". If I punched the buttons on my calculator properly, at 1.700" from the head of the 7.5 Swiss case, the outside diameter of the case is 0.4592".

Please let me know if these values are incorrect.

--Bob

-

pitted bore - Posts: 700

- Joined: Sun Jun 07, 2009 8:05 pm

- Location: The U.P.'s U.P.

Re: Alternate cases for forming 450 Bushmaster

Bob, thanks for doing the ground work on those dimensions.

The greater taper of the Swiss makes for a lot of stretching to get the mouth at 1.70 inches from the base to increase it's diameter from .459 to .480. As WC said, it's definitely doable.

Steps would go like this:

Buy a minimum lot size of 7.5x55 brass or mooch some in case it doesn't pan out.

Select 5 test cases or whatever amount you feel you need to try.

Chuck the cases in a lathe and turn the rims down to .466 ( Measure your Hornady brass is you don't believe me )

Turn the extraction grooves down to .398 ( Measure your Hornady brass is you don't believe me )

Using any of several methods, cut the cases down to 1.72 inches ( This is a guess. No telling how much they will shrink after stretching them wider)

Deburr inside and outside edges of the mouth.

Prime the cases and load them with fire forming charges. (I have a great process already for this part)

If you plan on using an AR 450b to fire form, rotate your gas block (This keeps burned filler out of of the gas system)

Fire the rounds, pausing to brush and patch the chamber and throat every couple of shots. ( You WILL get crud buildup the consistency of hardened tar)

Tumble your cases

Before resizing them Ream the necks with a .452 Forster Inside Neck Reamer to a depth of 5/8 inch. That should cover the longest bullet seat depth.

Resize the cases and check dimensions. (This may result in having to reassess the process)

Expect:

The cases will be have a stepped look to them since the web will not fire form up to .500 diameter. Hopefully you will not see weakening in the case head wall where the OD jumps suddenly from .493 to .500 after the web. Otherwise, you've just successfully prepped your brass for case head separation. The saving grace is that the walls are thicker there.

The cases will be shorter than the 1.72 they started out at. How much is a matter of concern as you can only cut the un-formed cases so long, to offset the shrinkage, and still be able to chamber them for fire forming.

Travails:

Of all the steps. IMHO, truing each case in an inexpensive mini-lathe may be the most difficult and time consuming part.

Factors: They are tapered, the lathe jaws are parallel, brass is softer than hardened steel and hollow brass tubing under the best circumstances will be a challenge to to get a good grip on without crushing it.

The need to get the cases zeroed out in the jaws so that your cut rims and extraction grooves are not out of round is important for reliable feeding.

Perhaps there is a case prep tool that uses a caliber specific collet, that you can buy. Once the collet is trued in the lathe jaws, you could feed the cases into it and turn down the rims and extraction grooves with repeatable accuracy. That is one very big and necessary IF to get past.

Not trying to be Mr. Doom & Gloom here, but plans need a good design review process before setting them in motion. Murphy Never Sleeps. I have a junk box full of Engineered-On-The-Fly, bright ideas, that stand as a testimonial to lack of thorough design review. Getting there was one of the greatest sources of entertainment for me, but that's just part of being Hoot...

The greater taper of the Swiss makes for a lot of stretching to get the mouth at 1.70 inches from the base to increase it's diameter from .459 to .480. As WC said, it's definitely doable.

Steps would go like this:

Buy a minimum lot size of 7.5x55 brass or mooch some in case it doesn't pan out.

Select 5 test cases or whatever amount you feel you need to try.

Chuck the cases in a lathe and turn the rims down to .466 ( Measure your Hornady brass is you don't believe me )

Turn the extraction grooves down to .398 ( Measure your Hornady brass is you don't believe me )

Using any of several methods, cut the cases down to 1.72 inches ( This is a guess. No telling how much they will shrink after stretching them wider)

Deburr inside and outside edges of the mouth.

Prime the cases and load them with fire forming charges. (I have a great process already for this part)

If you plan on using an AR 450b to fire form, rotate your gas block (This keeps burned filler out of of the gas system)

Fire the rounds, pausing to brush and patch the chamber and throat every couple of shots. ( You WILL get crud buildup the consistency of hardened tar)

Tumble your cases

Before resizing them Ream the necks with a .452 Forster Inside Neck Reamer to a depth of 5/8 inch. That should cover the longest bullet seat depth.

Resize the cases and check dimensions. (This may result in having to reassess the process)

Expect:

The cases will be have a stepped look to them since the web will not fire form up to .500 diameter. Hopefully you will not see weakening in the case head wall where the OD jumps suddenly from .493 to .500 after the web. Otherwise, you've just successfully prepped your brass for case head separation. The saving grace is that the walls are thicker there.

The cases will be shorter than the 1.72 they started out at. How much is a matter of concern as you can only cut the un-formed cases so long, to offset the shrinkage, and still be able to chamber them for fire forming.

Travails:

Of all the steps. IMHO, truing each case in an inexpensive mini-lathe may be the most difficult and time consuming part.

Factors: They are tapered, the lathe jaws are parallel, brass is softer than hardened steel and hollow brass tubing under the best circumstances will be a challenge to to get a good grip on without crushing it.

The need to get the cases zeroed out in the jaws so that your cut rims and extraction grooves are not out of round is important for reliable feeding.

Perhaps there is a case prep tool that uses a caliber specific collet, that you can buy. Once the collet is trued in the lathe jaws, you could feed the cases into it and turn down the rims and extraction grooves with repeatable accuracy. That is one very big and necessary IF to get past.

Not trying to be Mr. Doom & Gloom here, but plans need a good design review process before setting them in motion. Murphy Never Sleeps. I have a junk box full of Engineered-On-The-Fly, bright ideas, that stand as a testimonial to lack of thorough design review. Getting there was one of the greatest sources of entertainment for me, but that's just part of being Hoot...

In Theory, there is no difference between theory and practice. In Practice, there is.

-

Hoot - Posts: 5085

- Joined: Tue Feb 09, 2010 9:34 am

- Location: Minnesota

Re: Alternate cases for forming 450 Bushmaster

Hoot brought up some interesting ideas and questions about brass case dimensions in his posts above. Because I had not read the posts in the AR forum about the extractor difficulties, these points were new to me and pretty interesting.

To get first-hand info and insight into what was going on, I dug out three different batches of 450B cases, another batch of 284 Win, and two batches of 7.5x55 Swiss. I measured the diameters of the rims, extractor grooves, and case bodies (just in front of the extractor cut). My method was to select three cases randomly from each lot, and measure the diameters at three different edge locations on each case. I selected an arbitrary starting point, and measured at that point and at rotations of 60 and 120 degrees from the start. I used a pretty good Mitutoyo caliper, reading and recording to 0.0001", and rounding to the nearest 0.001" after finding averages.

All the brass except the 7.5x55 brass by Norma were new, unfired cases or cartridges. The 7.5x55 Norma had been fired 8 or 9 times with mild loads.

Here are the resulting averages:

.

.

There was not a lot of variability around the averages. At most, individual measurements differed from the average by +/- 0.001.

As a point of reference, here are the standards from SAAMI and CIP for these cartridges:

.

.

(Note that the standard max diameter for the head of the 7.5x55 case was given as 0.493 in a drawing in a post I made above. This smaller diameter was taken from a description of an actual cartridge, not the CIP standard drawing. My oopsie.)

Again, I wasn't out to prove or disprove anything with these measurements. I wanted to scratch a curiosity itch, and learn more about the possibilities of converting 7.5x55 brass to 450B.

Interesting Point #1: From the standards table: All the diameter max/min standards for the 450B and the parent 284 Win cartridge are identical, except for the extractor groove minimum. Among SAAMI-approved rimless cartridges, the 450B is unusual in having extractor groove diameter with a minimum of only 0.010 less than the max. Almost all others have a minimum of 0.020 less than max. Even much smaller cartridges like the 223 have the same 0.020 tolerance.

This oddity in tolerance is not tied to having a rebated rim, because the 284, the parent cartridge of the 450B, has a min 0.020 less than the max.

Interesting Point #2: With one exception, the diameters of all the individual cases I measured for the three different cartridges are all within SAAMI/CIP tolereances. The Rim Dia of the 284 has a tolerance of 0.473 max to 0.463 min. The measured average diameter was 0.468, which is exactly in the middle of the tolerance range.

The exception is the extractor groove diameter for the two lots of Hornady 450B cases. At 0.398 and 0.396, they are 0.001 and 0.003 less than the minimum allowable diameter. This corroborates Hoot's observation of the extractor groove in the Hornady ammo being less than standard.

Interesting Point #3: If the 450B had the same tolerance as the 284 (min of 0.020 less than max), the Hornady 450B cases would be well within the allowable groove diameter tolerance.

Interesting Point #4: The rim diameters of all the cartridges are within tolerance limits.

Interesting Point #5: Relative to Hoot's note about the extractor problems with 284 ammo being used in 450B ARs: Were there any reported difficulties with the use of the 450B cartridges manufactured by Remington?

Interesting Point #6: Measurements of the 7.5x55 case head dimensions indicate that turning down the rim by 0.020 and thinning the rim appropriately should produce cases that are usable in at the hind end. The front end will need relatively more work.

Other interesting points about these measurements will surely occur to readers.

--Bob

To get first-hand info and insight into what was going on, I dug out three different batches of 450B cases, another batch of 284 Win, and two batches of 7.5x55 Swiss. I measured the diameters of the rims, extractor grooves, and case bodies (just in front of the extractor cut). My method was to select three cases randomly from each lot, and measure the diameters at three different edge locations on each case. I selected an arbitrary starting point, and measured at that point and at rotations of 60 and 120 degrees from the start. I used a pretty good Mitutoyo caliper, reading and recording to 0.0001", and rounding to the nearest 0.001" after finding averages.

All the brass except the 7.5x55 brass by Norma were new, unfired cases or cartridges. The 7.5x55 Norma had been fired 8 or 9 times with mild loads.

Here are the resulting averages:

.

.

There was not a lot of variability around the averages. At most, individual measurements differed from the average by +/- 0.001.

As a point of reference, here are the standards from SAAMI and CIP for these cartridges:

.

.

(Note that the standard max diameter for the head of the 7.5x55 case was given as 0.493 in a drawing in a post I made above. This smaller diameter was taken from a description of an actual cartridge, not the CIP standard drawing. My oopsie.)

Again, I wasn't out to prove or disprove anything with these measurements. I wanted to scratch a curiosity itch, and learn more about the possibilities of converting 7.5x55 brass to 450B.

Interesting Point #1: From the standards table: All the diameter max/min standards for the 450B and the parent 284 Win cartridge are identical, except for the extractor groove minimum. Among SAAMI-approved rimless cartridges, the 450B is unusual in having extractor groove diameter with a minimum of only 0.010 less than the max. Almost all others have a minimum of 0.020 less than max. Even much smaller cartridges like the 223 have the same 0.020 tolerance.

This oddity in tolerance is not tied to having a rebated rim, because the 284, the parent cartridge of the 450B, has a min 0.020 less than the max.

Interesting Point #2: With one exception, the diameters of all the individual cases I measured for the three different cartridges are all within SAAMI/CIP tolereances. The Rim Dia of the 284 has a tolerance of 0.473 max to 0.463 min. The measured average diameter was 0.468, which is exactly in the middle of the tolerance range.

The exception is the extractor groove diameter for the two lots of Hornady 450B cases. At 0.398 and 0.396, they are 0.001 and 0.003 less than the minimum allowable diameter. This corroborates Hoot's observation of the extractor groove in the Hornady ammo being less than standard.

Interesting Point #3: If the 450B had the same tolerance as the 284 (min of 0.020 less than max), the Hornady 450B cases would be well within the allowable groove diameter tolerance.

Interesting Point #4: The rim diameters of all the cartridges are within tolerance limits.

Interesting Point #5: Relative to Hoot's note about the extractor problems with 284 ammo being used in 450B ARs: Were there any reported difficulties with the use of the 450B cartridges manufactured by Remington?

Interesting Point #6: Measurements of the 7.5x55 case head dimensions indicate that turning down the rim by 0.020 and thinning the rim appropriately should produce cases that are usable in at the hind end. The front end will need relatively more work.

Other interesting points about these measurements will surely occur to readers.

--Bob

-

pitted bore - Posts: 700

- Joined: Sun Jun 07, 2009 8:05 pm

- Location: The U.P.'s U.P.

Re: Alternate cases for forming 450 Bushmaster

Ok, as we are speculating with an actual end result and assuming you have some sort of lathe. I did, many years ago, spin the belts off of one of the belted magnums, rebated the rim and successfully passed it a 284 sizer die, of course I had to ream the inside neck. This was way more work than I wanted to do, but, it can be done. The accuracy will prolly suffer some, but we do have room to suffer a little, but this new FrankenCase will go Boom and will efficiently kill Pigs, Deer or..

..t

..t

Safety First..t

-

wildcatter - Posts: 2914

- Joined: Sat Jun 06, 2009 8:30 pm

- Location: In the Middle of Deer Central Station or better known as, in the Thumb of Beautiful Michigan

22 posts

• Page 2 of 3 • 1, 2, 3

Return to Reloading for the 450b

Who is online

Users browsing this forum: No registered users and 77 guests